Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Flame arresters are used in acetylene pipelines to interrupt the combustion of flames, which may attain high speeds, and cause heavy damage unless they are stopped. These devices feature heat sinks having a high surface-to-volume ratio, as well as narrow passageways such as woven wire gauzes, parallel metal plates, or porous metal plates that are proven to quench the flame. The metal components used in these devices help reduce the speed of flame and also absorb heat, thereby inhibiting from crossing the flame arrester.

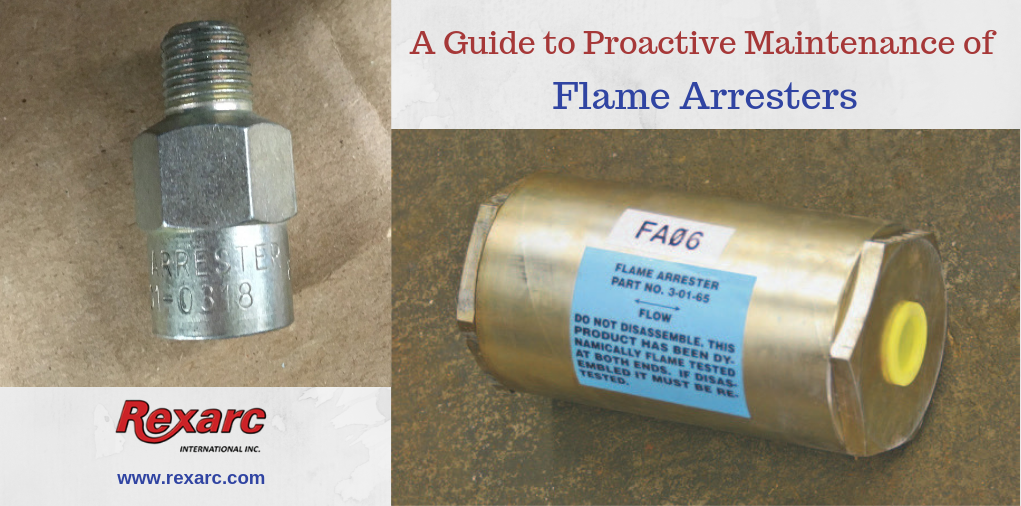

The flame arresters are nowadays being widely used in acetylene cylinder filling plants to stop the spreading of flame during cylinder filling. Rexarc is one of the leading manufacturers of acetylene plants, since 1924, and this makes it one of the leading flame arrester manufacturers in the US. The company offers two types of flame arresters— small flame arresters (1-01-0318) and large arresters (3-01-0065). This post discusses the importance of these devices as well as the steps for easy flame arrester maintenance.

How do Flame Arresters 1-01-0318 & 3-01-0065 Work?

In the event of ignition at a cylinder, the small flame arresters (1-01-0318) limit the ignition to the individual cylinder. If the ignition occurs in the manifold, it never reaches the cylinder. The larger arresters (3-01-0065) stop the flame originating in the manifold from traveling upstream toward the high-pressure dryers or a flame originating upstream from traveling downstream to the manifolds.

Both flame arresters are dynamically tested at the factory to ensure proper protection. Once tested at the factory, the flame arresters need only be checked for flow. If the flame arresters’ flow rates are below the recommended test value, they will prevent the cylinders on the manifold lines from properly being filled and hence should be replaced. Flow rates are affected by impurities in the acetylene stream such as ammonia. Ammonia when compressed will turn into a brownish-black gunk that will plug all flame arresters. Therefore, it is important to use an ammonia scrubber before the compressor.

1-01-0318 Flame Arresters

Flame arresters provide damage protection should ignition or detonation occur in the high-pressure acetylene lines. As most incidents start in the valves, flame arresters stop the propagation at the earliest stage. On Rexarc charging manifolds, these flame arresters are installed before and after the outlet valves and at the cylinder connection, which has a check valve in the connection stem. Many customers replace these flame arresters on a 2-year cycle and others that replace them on an as-needed basis with the bulk lasting five years or more.

The criteria being the extent of the pressure drop and/or flow restriction.

3-01-0065 Flame Arresters

The master valves are protected using 3/4″ flame arresters, 3-01-0065.

Rexarc’s 3-01-0065 flame arrester will clog over time if impurities or moisture are left in the acetylene stream. This will cause the pressure to rise on the compressor side and be lower on the manifold side. One of the important causes is moisture in the acetylene stream. This moisture will cause the silicon carbide inside the flame arrester to fuse together causing a pressure rise downstream of the flame arrester. The easiest method to test if it is starting to restrict is that the flame arrester will be it is cold when touched. A maximum of 50 PSI differential pressure usually means it needs to be replaced.

Tips for Safe and Quick Inspection and Flame Arrester Maintenance

The flame arresters must be inspected and serviced on a regular basis to ensure their effectiveness. The element of the flame arrester must be inspected for clogging and the aforementioned issues at regular intervals. However, the frequency of inspections will entirely depend on the application. It is always recommended to perform the flame arrester maintenance if you notice an excessive pressure drop at a known flow rate.

If you are doing the inspection or flame arrester maintenance for the first time, and require some help, it is always better to approach experts at Rexarc. Being a leading flame arrester manufacturer in the US with a vast experience to its credit, the experts at Rexarc will guide you through the steps of regular inspection and proactive maintenance of flame arresters.

We are a one stop shop from custom vessel production to full skidding, plumbing and instrumentation.

We stand by our processes and communicate with you on your project status as much or as little as you would like.

We continually reinvest in our people, business, and equipment technology to ship quality products on time.