Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Acetylene is a combustible gas with a distinctive odor. It is used as a raw material for the production of several organic chemicals, as well as a fuel component in metal cutting, and oxy-acetylene welding. Today, acetylene is also used in the production of several plastics. Typically acetylene is produced by either one of the following methods:

With each method having its own advantages, the choice will entirely depend on the user. In this post, we will discuss the production of acetylene using calcium carbide in the acetylene generator.

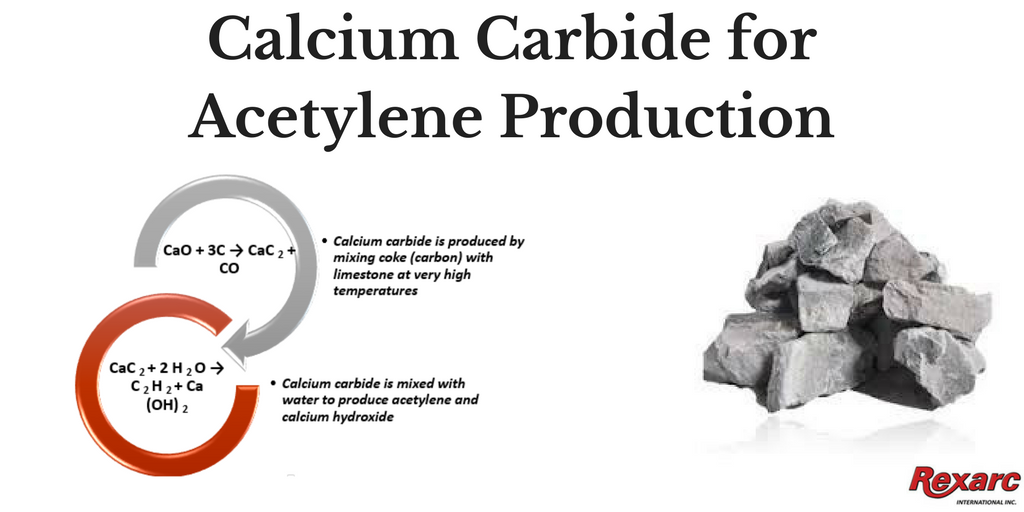

In various industrial environments, acetylene generation is initiated in acetylene producing generators. These equipment are sold in various capacities from 8 m3 to over 200 m3 per hour. Calcium carbide is introduced from the top of the generator shell into the water. The chemical formula of this reaction can be expressed as:

CAC2 + 2 H2O → C2H2 + CA(OH)2

This reaction should only be conducted under controlled conditions. The process unit should be equipped with pressure and temperature sensors, as well as non-return valves for safety purposes.

Components of acetylene generation plant and their individual contribution is described here:

Generator: Here, calcium carbide is mixed with a large quantity of water to produce acetylene gas. The generator is fitted with the following accessories:

a. Automatic control sensors

b. Feeder

c. Hopper(s)

d. Agitator

e. Arrestor

Condenser: It helps cool down the acetylene gas produced in the generator.

Ammonia Scrubber: This vessel removes ammonia from the acetylene stream before purification.

Medium Pressure Drier: As the name suggests, the medium pressure drier helps dry the acetylene gas. It is also used to control the moisture content of the acetylene stream into the purifier. Anhydrous calcium chloride is used for the purpose.

Purifier: It mainly comprises of a purifying material, which helps separate phosphine and hydrogen sulphide created during the acetylene generation.

Purifier Scrubber: This component keeps any purifying material from entering the compressor.

Compressor: Acetylene is a flammable gas. It uses a compressor for acetylene that is surrounded by water, which cools the heat of compression after each stage.

The following are some guidelines that should be adopted while handling calcium carbide during acetylene generation.

The maximum permissible size and weight of the carbide for a single charge should be matched with the equipment manufacturer’s specification.

Calcium carbide should be kept in air and water tight metal packages, and labelled “Calcium Carbide – Dangerous If Not Dry”.

Calcium carbide in drums should not exceed 250 kg. It should be stored where water cannot enter. Containers should be regularly checked to see that water has not entered.

Calcium carbide drums shall only be opened at the time of filling carbide to hoppers.

Carbide with more than 15% dust concentration shouldn’t be charged in the generator.

The carbide-water residue should not be discharged into the environment directly.

The size of the calcium carbide is an important consideration during the production of gas. The following information will give you an idea of the best grades.

|

Grade Size

|

Quantity A | Gas Yield Liter Per Kg Quantity B | Cu.ff per lb. Quantity A | Quantity B |

| 15-80 | 311 | 288 | 4.98 | 4.60 |

| 7-15 | 301 | 275 | 4.81 | 4.42 |

| 4-7 | 287 | 267 | 4.59 | 4.28 |

| 2-4 | 273 | 251 | 4.36 | 4.01 |

| 1-2 | 257 | 236 | 4.25 | 3.77 |

The above mentioned information regarding best sizes for gas yield is compiled from several industrial studies. You can always approach an industry expert like Rexarc to understand the best sizes for your application requirement. The company produces industry-grade acetylene plants in various specifications and dimensions. Yield could be different between various manufacturers.

We are a one stop shop from custom vessel production to full skidding, plumbing and instrumentation.

We stand by our processes and communicate with you on your project status as much or as little as you would like.

We continually reinvest in our people, business, and equipment technology to ship quality products on time.