Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

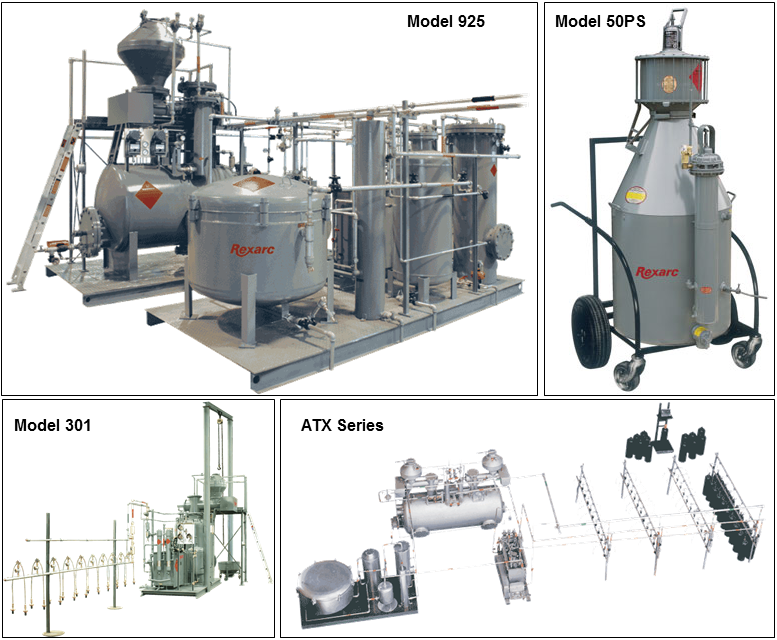

The state of components and equipment in an acetylene plant will determine the efficiency and safety of the plant. Since acetylene is a volatile substance, excessive care should be taken to maintain the equipment used to handle it. Identifying the problem, developing a solution, and maintaining the product are crucial to safe operation within an acetylene plant. Audits form an integral part of preventive maintenance. It is one of the best practices to be employed by all acetylene plant owners.

Below are listed some common problems observed during acetylene plant audits and methods on how to avoid them during maintenance:

1. Problem: High water level alarm has been disabled by drilling a hole through the restriction tee fitting. This was done to get more air pressure through the unit and to compensate for air leaks and lower pressure upstream in the air control system.

Solution: Firstly, all air leaks in the system need to be fixed. Additionally, a new restriction tee needs to be installed.

How to Avoid It: Corrosion causes the aluminum air tubing to corrode which causes the air system to leak and/or become clogged. This can be remedied by replacing all of the aluminum tubing with new stainless steel tubing.

2. Problem: Since the air fitting connections were leaking, the restrictors had been drilled out to drain the water. This is a temporary solution, which solved one problem but created a few more as addressed in problem #1.

Solution: The leak should be stopped immediately. All aluminum tubing should then be replaced by stainless steel tubing.

How to Avoid It: The easiest way to avoid this problem is to use stainless steel tubing exclusively as the preferred material for all control air tubing, excluding plant emergency stop tubing which recommends plastic tubing. It is important to use the appropriate material for other components as well. Components that are exposed to corrosion or inducing materials like moisture, chemicals, etc. should be coated with the appropriate materials.

3. Problem: When the level control unit was not working, it was hit with a wrench to unstick internal movement of components. This caused the tube to lose its shape, worsening the functioning of the same. The control tube was frozen since it was hit too many times.

Solution: The tube cannot be fixed since it has lost its shape. It needs to be replaced.

How to Avoid It: Certified products and components need to be used in an acetylene plant. Using non-approved products can reduce the life of the other components.

With reference to acetylene plants, some common problems, their solutions, and steps on how best to avoid them have been covered in this post. In the following posts, some more problems will be identified. Stay tuned!

We are a one stop shop from custom vessel production to full skidding, plumbing and instrumentation.

We stand by our processes and communicate with you on your project status as much or as little as you would like.

We continually reinvest in our people, business, and equipment technology to ship quality products on time.