Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

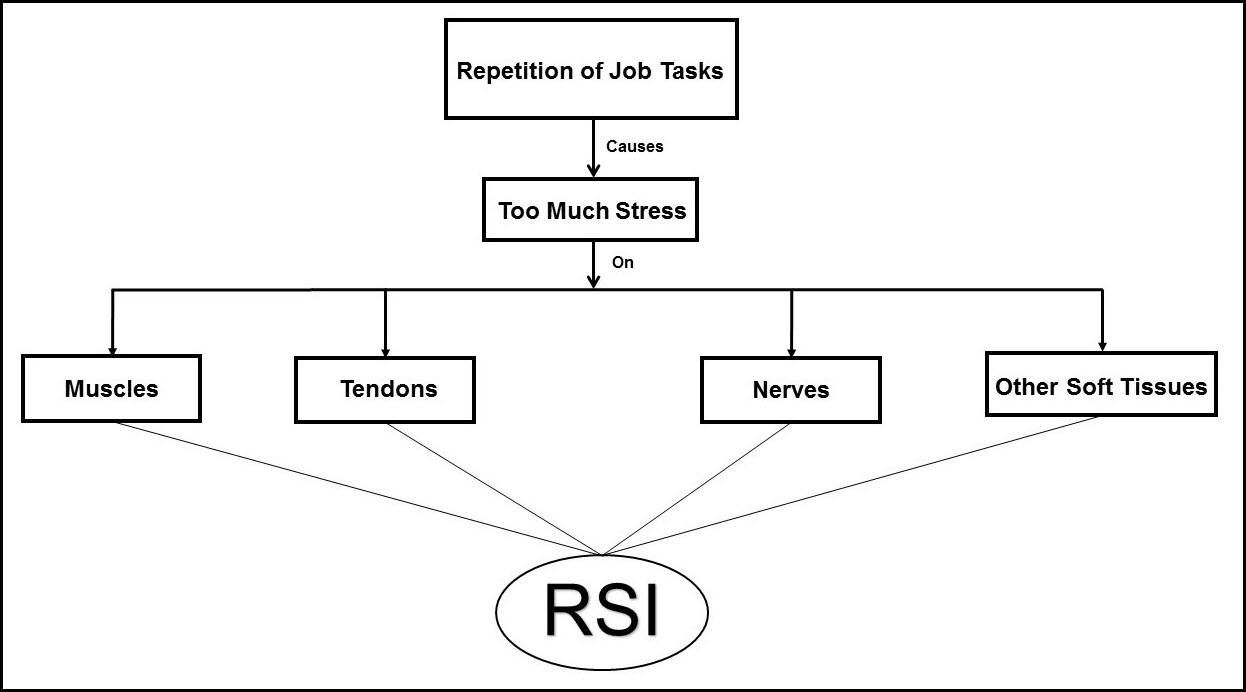

In a job, an employee might be required to perform the same job repeatedly. Such repetitive motions have the potential to cause serious injury to the employee. In acetylene plants, several such jobs can be identified that could cause physical injury to a large extent. Known as Repetitive Strain Injury (RSI) and Cumulative Trauma Disorder (CTD), these injuries cause musculoskeletal disorders (MSDs). With continuous strain on the body part over a long period of time, it is likely that the nerves will also get affected. This poses several health risks.

RSI Has the Potential to Cause Serious Long-term Health Problems

Repetitive Strain Injury in Acetylene Plants & How to Avoid It

An action performed continuously over a period of time causes repetitive strain injury. This problem is aggravated when pressure related movements are performed. Twisting in particular can cause serious injuries if performed continuously for a long period.

In acetylene manufacturing plants, acetylene cylinders are connected to hoses and cylinder connections to transfer acetylene or acetone. This requires the technician to twist the acetylene cylinder hand wheel constantly. Such repetitive motions like hand cranking can lead to injuries. Twisting the hand wheel repetitively adds a lot of pressure on the wrist leading to RSI.

PROBLEM: Undesirable Repetitive Turning

SOLUTION: Quick Connects

Rexarc has developed a product in collaboration with WEH – the Acetylene and Acetone Quick Connect. It helps in reducing the effort taken when twisting cylinder hand wheels. The quick Connect is mainly used during the weighing in and weighing out process as well as with smaller cylinders that require a wrench to tighten prior to filling. With Quick Connects, 50% of hand cranking motion can be reduced. This helps increase efficiency and reduces chances of workplace injuries.

How Automation Helps Reduce Chances of RSI in Acetylene Plants

There are two chief methods of reducing chances of RSI. One is to adopt an ergonomically sound posture at all times. The second solution is automation. It is extremely important to identify the tasks that require repetitive motion, and engineer an automated solution for the same. This has proven to be the most effective solution there is to avoid workplace injuries related to repetitive motion in acetylene plants. Automation not only helps reduce injuries, it also helps increase employee efficiency. Hence, such activities should be identified and automated at the earliest.

Benefits of Using Quick Connects In Your Acetylene Plant

You can enjoy the following benefits of incorporating ‘Quick Connects’ for acetone and acetylene service:

Reducing RSI Instances: Importance of Posture

Along with utilizing automation and progressive technology to reduce repetitive motion in acetylene plants, it is also important to maintain the right posture when performing any task. One solution cannot be complete without the other. Wrong postures and machine handling positions can lead to problems more severe than the ones posed by repetitive motion. Hence, proper education on correct postures, as well as ergonomic work environments can help in reducing workplace injuries.

Opt for Improved Automated Methods

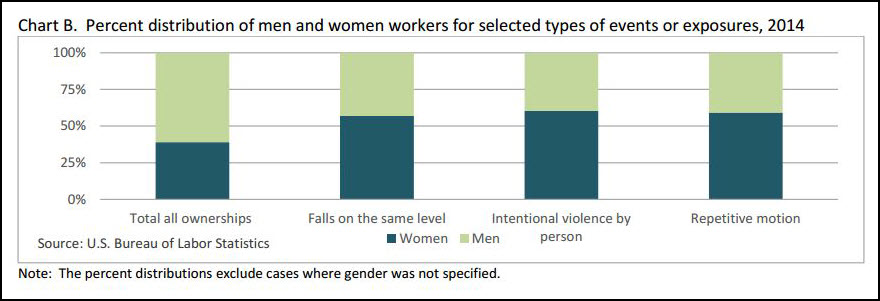

Musculoskeletal disorders (MSDs) accounted for 32% of all injury and illness cases in 2014

(Source: OSHA)

For any businessperson, such numbers mean havoc – Repetitive motion related injuries account for over 30% of injuries occurring at the workplace. It is by far the highest cause for injuries. Acetylene plant owners should take these facts into consideration when setting up a new plant or upgrading an old one. Identifying plant areas where maximum number of injuries take place will allow plant owners to make a decision that optimizes production processes and systems.

In order to reduce chances of such injuries and increase employee efficiency, certain procedures and machines can be improved. Along with reducing instances of workplace injuries, the following benefits can be acquired by a business:

All of this translates positively on the plant floor, in financials, and in every aspect of the organization.

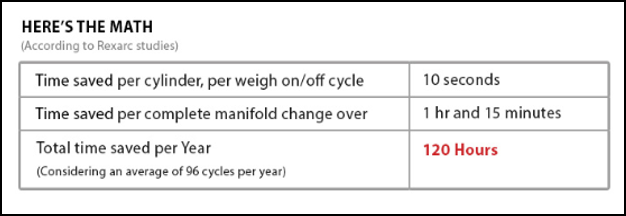

For example, the Quick Connect can help reduce effort taken when accessing a cylinder. There is concrete evidence that proves this:

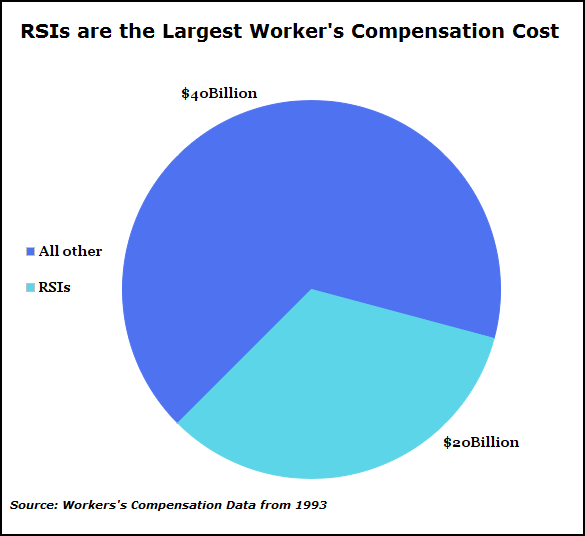

Below is another statistic that shows that over $20 billion is spent as compensation for RSI-related problems.

Further Reading

For further reading, please refer to grant number SH-22310-11-60-F-6 from the Occupational Health and Safety Administration, U.S. Department of Labor.

We are a one stop shop from custom vessel production to full skidding, plumbing and instrumentation.

We stand by our processes and communicate with you on your project status as much or as little as you would like.

We continually reinvest in our people, business, and equipment technology to ship quality products on time.