Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Huge amounts of industrial waste are generated around the world. This waste can be harmful to the environment if not disposed properly, or the disposal of the same could lead to very high costs. On the other hand, utilizing industrial waste as secondary raw materials for other industries could not only reduce costs and save the planet, but also serve as a supplementary source of income. Since lime is used in several industries, lime slurry can be treated and used in many applications.

The rising rates of carbide lime waste (CLW), commonly known as lime slurry produced as a byproduct of industrial production of acetylene, has warranted the need for repurposing of the said material.

How Lime Slurry Is Produced in the Acetylene Production Process?

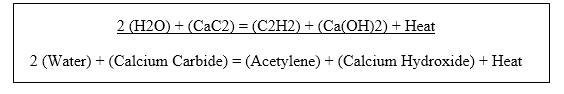

In the acetylene production process, carbide is mixed with water to produce acetylene, carbide lime or lime slurry, and heat.

The formula for this process:

The final products are suspended in water. Thus, when calcium hydroxide mixes with water, it produces CLW.

Once, the water is evaporated or dried, the lime slurry produced is in solid form. This makes disposal tedious and expensive. Hence, utilization of lime slurry in other industrial applications has proved to be beneficial for both the suppliers and users.

In the initial stages, several chemical tests and X-ray diffraction analysis were carried out to determine the constituents of lime slurry. It was noted that with the exception of presence of carbon, lime slurry was very similar to industrial lime. Hence, the process of treating and repurposing lime slurry was put in place.

Methods of Repurposing Lime Slurry

Once seen as a liability and cost, proper repurposing of lime slurry can bring in a profit. Here are listed some methods of re-using carbide lime waste:

Repurposing Lime Slurry: Points of Consideration

If, as a manufacturer, or intermediary, you consider getting into the lime slurry market, you need to consider the following factors:

The industrial waste produced by acetylene manufacturing plants can prove to be a boon. Manufacturing and processing methods and applications can be adjusted for effective usage of lime slurry. Using the byproducts of one industry as the raw material of another can help in providing a better industrial working culture. This method not only saves costs, increases employment, reduces wastage, and makes the planet greener.

We are a one stop shop from custom vessel production to full skidding, plumbing and instrumentation.

We stand by our processes and communicate with you on your project status as much or as little as you would like.

We continually reinvest in our people, business, and equipment technology to ship quality products on time.