Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

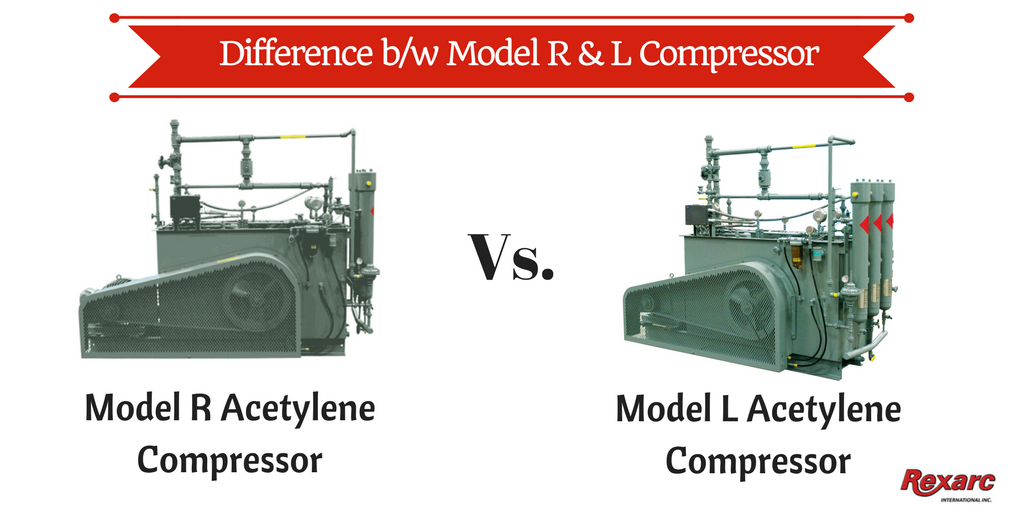

This is a common question when a company asks about the compressor options available from Rexarc. Here’s a brief overview of the similarities between the Rexarc Model L and Model R acetylene compressors as well as the positives and negatives of each of the differences.

There are also several differences between the Rexarc Model L and Model R compressors. Here’s an overview of the differences, as well as the positive and negative of that difference.

|

Difference |

Positive(s) of Difference |

Negative of Difference |

|

Model L has a heavier casted crank case and cylinder jugs. |

Longer lasting. |

– |

|

Model L has Machined Heads |

Longer lasting. |

– |

|

– |

Should water enter the compressor, the heads are more durable. |

– |

|

Model L crankshaft is supported at each end by a set of bearings. |

Should water enter the compressor, the crank shaft rarely breaks. |

– |

|

Model L has an internal and external oil pump. |

Better lubrication of compressor parts which leads to increased life. |

– |

|

Model L and Model R have different mounting and plumbing. |

– |

Changing from a Model R to a Model L requires complete unit replacement, not just the bare compressor. |

|

Model R is an Ingersol Rand based compressor |

Spare parts are more readily available throughout the world. |

Some parts are modified by Rexarc to align to acetylene compressing. |

|

Model L is a Gardner Denver based compressor |

– |

Spare parts are not as readily available. Customers often stock parts to ensure fast local availability. |

|

– |

– |

Customer may have to stock two sets of spares if more than one compressor is in use and they are going through a model transition/upgrade. |

|

– |

– |

Parts are more generally more expensive. |

There are several similarities as well as differences when considering which model to purchase for the first time or replace when upgrading. Here is how your partner at Rexarc can support the various challenges.

We are a one stop shop from custom vessel production to full skidding, plumbing and instrumentation.

We stand by our processes and communicate with you on your project status as much or as little as you would like.

We continually reinvest in our people, business, and equipment technology to ship quality products on time.