Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

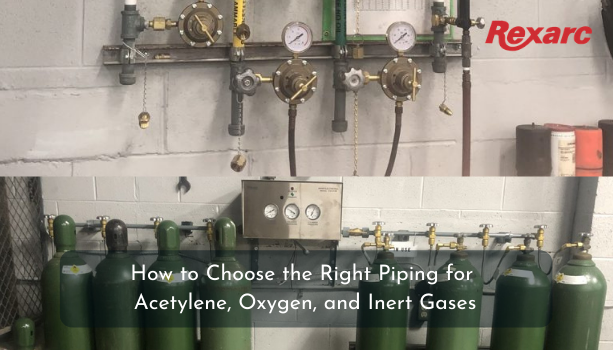

Acetylene, oxygen, and inert gases are industrial gases, which find applications across industries. Oxygen-acetylene combination produces localized heat, and is widely used for different types of heating applications. Be it acetylene, oxygen, or inert gases, each of these have typical flammability characteristics, which possess challenges to their storage and handling. These gases are stored in gas plants and cylinders and distributed through piping and manifolds. The piping and manifolds feature different components, which are designed to specifications and are made carefully using different materials. The choice of material for piping and manifolds is a rigorous process and it requires several considerations. This post discusses the factors to be considered when building piping for acetylene gas, as well as oxygen and inert gases.

Factors of Consideration for Oxygen, Inert Gas, and Acetylene Manifold Piping Systems

As said before, each gas has typical characteristics which must be addressed while designing piping systems for acetylene, oxygen, and inert gas. The following pointers will give a brief idea of how these gases act and things to be kept in mind while choosing the sizing and materials for pipelines and piping.

Acetylene

Oxygen

Argon and Nitrogen

Going by the descriptions, it is much clear that one needs to take much care when designing acetylene and oxygen piping systems. The acetylene and oxygen pipe sizing calculator takes into consideration the application requirements.

Know About the Materials Used in Inert Gas, Oxygen, and Piping for Acetylene Gas

The use of burn-resistant metals or metal alloys are recommended for piping or manifold piping and pipeline system installation. The following are a few common materials used in oxygen, acetylene, and inert gas piping.

It is always ideal to discuss with an expert before laying pipelines for the transportation of gases. They would be able to help you with the right material after understanding your application requirements. With all these, it is also important to invest in quality systems like acetylene plants or gas manifolds. Rexarc specializes in acetylene plants and cylinders as well as gas manifolds. You can get in touch with the team today to discuss your requirements.

We are a one stop shop from custom vessel production to full skidding, plumbing and instrumentation.

We stand by our processes and communicate with you on your project status as much or as little as you would like.

We continually reinvest in our people, business, and equipment technology to ship quality products on time.