Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Did you know that ASME vessels play a vital role in wastewater treatment, ensuring safe and efficient operations? Here are some ways they are utilized; Chemical Storage: ASME pressure vessels are commonly used to store various chemicals involved in wastewater...

View Details

Did you know ASME vessels play critical roles in rocket engine test stands? Their certification and safety requirements are crucial in the development and certification of rocket engines as they are tested on the ground before they are used in...

View Details

Understanding and selecting coating options for wastewater treatment vessels is essential to extending the lifespan of tanks, pipes, and other equipment while also ensuring their structural integrity. Specialized coating systems provide a necessary barrier that protects against the harsh chemicals...

View Details

Pressure vessels play a large role in many water treatment methods. Water treatment is used to remove contaminants from water used for drinking, washing, and cooking, among others, so it’s a critical industry that everyone uses at some point. This...

View Details

Pressure vessels are designed with multiple key safety features so they can be used safely for whatever requirements they are rated for, as long as they are properly maintained. Without these safety features, pressure vessels can fail and cause serious...

View Details

Pharmaceutical manufacturing is a far-reaching, global industry that plays a role in your everyday life. Pressure vessels are used extensively in this industry to develop and transport medicines and the chemicals used to make them, but why are they such...

View Details

Maybe you’ve had an old pressure vessel sitting around for a while, either in use or in storage. How do you know if it’s safe to use for a new project or if you should invest in a new one?...

View Details

Pressure vessels play a major role in the development and deployment of renewable energy systems. Investing in renewable energy is an important part of developing a robust network of energy suppliers that are more sustainable long-term. In this article, we’ll...

View Details

Dynamic loads are one of the more complex types of applied forces to account for. It’s important to understand what they are and when you’re likely to run into them, since they can have a big impact on how your...

View Details

When engineers design pressure vessels, they take into account many types of forces acting on the vessel, such as static loads, in order to ensure the vessel can withstand those forces. Understanding what forces are applied and how the system...

View Details

Pressure vessels are used extensively in the food and beverage industry. It’s one of the largest industries using them, and no matter where you are, you’ve likely eaten or drank something that required a pressure vessel during its manufacturing, storage,...

View Details

Nondestructive testing (NDT), also known as nondestructive inspection (NDI), is a critical step of pressure vessel development. When a vessel is built, it has to be tested to make sure it was built properly and can be operated safely without...

View Details

Personal protective equipment (PPE) is gear that exists to keep people safe on the job. There are some regulations set out by the Occupational Safety and Health Administration (OSHA) to ensure workplaces are doing what they can to protect their...

View Details

One major user of pressure vessels is the chemical industry. They use many different sizes and types of pressure vessels to process, store, and transport chemicals for use in everyday life – everything from bottled soda to the cooling system...

View Details

Determining the material choices is one of the most critical steps of designing a pressure vessel. If you’ve decided that stainless steel is the right material for you, you will also need to know what grade of stainless steel you...

View Details

There is a lot of jargon when it comes to pressure vessels, and k-bottles are a good example. You might have seen k-bottles annotated in a schematic or diagram, or listed in an email from a colleague, but do you...

View Details

ASME standards are used by engineers, manufacturers, and other professionals across the globe to make sure designs and parts meet certain requirements. These requirements are important because they demonstrate a commitment to safety and quality in the created products. This...

View Details

If you have a pressure vessel or are in the process of purchasing one, you might be wondering how to get it ASME certified. ASME certification means the vessel meets industry standards for design and manufacturing, and will ensure you...

View Details

Have you ever wondered how stainless steel is rolled into a cylinder to form a pressure vessel? It’s a manufacturing process that requires specialized equipment and trained experts to perform. See it in action below: [embed]https://www.youtube.com/watch?v=slHATiDc7-8[/embed] Why roll stainless steel...

View Details

Figuring out the budget for a project can be a complicated process even if it’s a simple one, and adding custom work can make it more complex. It’s important to have a good idea of how much a project will...

View Details

Many people think stainless steel can’t be affected by rust, but this isn’t true. No strategy to prevent corrosion is perfect. This article will help you understand how rust can impact your projects using stainless steel, and when you might...

View Details

Stainless steel is often an economical, easily-machined option for a pressure vessel material, but there’s a lot to consider when choosing your materials. Is stainless steel the best option for your project? What other options are out there? What materials...

View Details

Choosing the right material for your pressure vessel is one of the most critical design choices to make. Stainless steel is one of the most popular choices, but do you know why it’s a great material to build a pressure...

View Details

Deionized water tanks are used to store water that has had most of a particular type of contaminant removed. To keep the water from regaining this contaminant, special measures must be taken. This article will go over what deionized water...

View Details

If you’re working with steel tanks and pressure vessels, you’ve probably heard of hydrogen embrittlement. It’s a type of corrosion that affects many metals when exposed to atomic hydrogen. This article will help you understand why it’s important, how it...

View Details

There are many subcategories of vessels used to hold liquids like DOT cylinders, tanks, and pressure vessels. They each have their own distinctions and uses. This article will help you figure out what type of vessel you need and what...

View Details

Pressure vessels are designed to maintain a difference in pressure between the vessel’s interior and the environment. They’re used across industries including aerospace, manufacturing, transportation, and more, but even though they’re common they have some particular design requirements that need...

View Details

Pressure vessels are used across dozens of industries in everything from researching new technologies to studying the stars. They’re highly specialized pieces of equipment with specific design requirements to ensure the safety of the people using them, so while there...

View Details

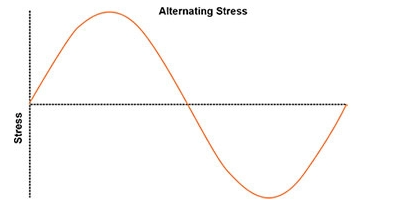

There are many types of loads and stresses that pressure vessels will encounter while they’re being used, including cyclic loading. So what is cyclic loading, and how does it impact the life of a pressure vessel? What type of load...

View Details

Preface Pressure vessels have stringent design requirements to ensure they will operate safely under the specialized loads and stresses they experience. This technical report contains a detailed analysis of metal fatigue caused by cyclic loading and early indicators of fatigue in high pressure stainless...

View Details

Have you ever wondered what propels rockets out of the atmosphere and into the stars? Maybe you’ve seen the trail they leave behind as they streak through the sky, burning up their fuel. This article will go over the most...

View Details

Corrosion is an inevitable part of maintaining a stainless steel pressure vessel, so how do you know when the amount of damage is too much to safely operate your vessel? What types of corrosion attack stainless steel? Stainless steel has...

View Details

Wondering how long your stainless steel will keep its corrosion resistance? It depends on the type of materials involved and how the object in question was designed. We’ll go over what stainless steel actually is, how it works, and if...

View Details

Cryogenic cooling combines heat transfer with low temperature physics to cool systems below about -250 degrees Fahrenheit (or -150 degrees Celsius, or 120 Kelvin), which is far colder than Antarctica, the coldest place on Earth. It’s a complex science, requiring...

View Details

Maybe you’ve got one lying around in the lab from a previous experiment, or you’ve found one being sold online at a cheaper price. But is it safe to reuse a stainless steel pressure vessel? It depends on several factors:...

View Details

Stainless steel pressure vessels have rounded ends as part of their design so they can safely contain their high pressure contents. Pressure applies a force over the entire surface area of the vessel. Rounding the ends prevents stress from building...

View Details

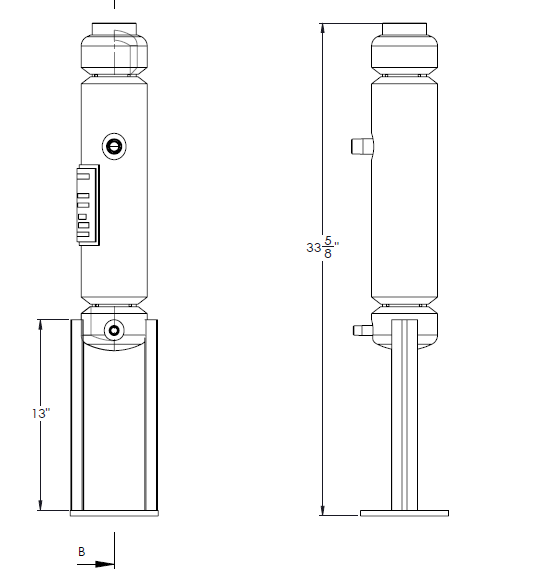

Sometimes the parts you need aren’t sold on the shelves. Rexarc ran into this problem trying to find the best fittings for our stainless steel pressure vessels, ones that would meet ASME standards for the very high pressures our vessels...

View Details

Rexarc’s commitment to working with customers on their projects has spearheaded the company’s ability to redefine industries since 1924. Our continuous evolution has taught us what strategies give our customers the support and information they need throughout the project lifecycle...

View Details

A stainless steel pressure vessel is a type of container designed to hold its contents at pressures above 15 psig (that’s 15 pounds of force applied per square inch, relative to atmospheric pressure). Pressure vessels withstand high pressures, applied externally...

View DetailsThis content is password protected. To view it please enter your password below: Password:

View Details

Questions to Ask to make your project go smoothly Discussing Stainless Steel Tank Expectations Leads to Best Outcomes When engaging a potential fabricator, have a discussion with that manufacturer to help them understand how your tank will be used, the...

View Details

We are a one stop shop from custom vessel production to full skidding, plumbing and instrumentation.

We stand by our processes and communicate with you on your project status as much or as little as you would like.

We continually reinvest in our people, business, and equipment technology to ship quality products on time.