Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

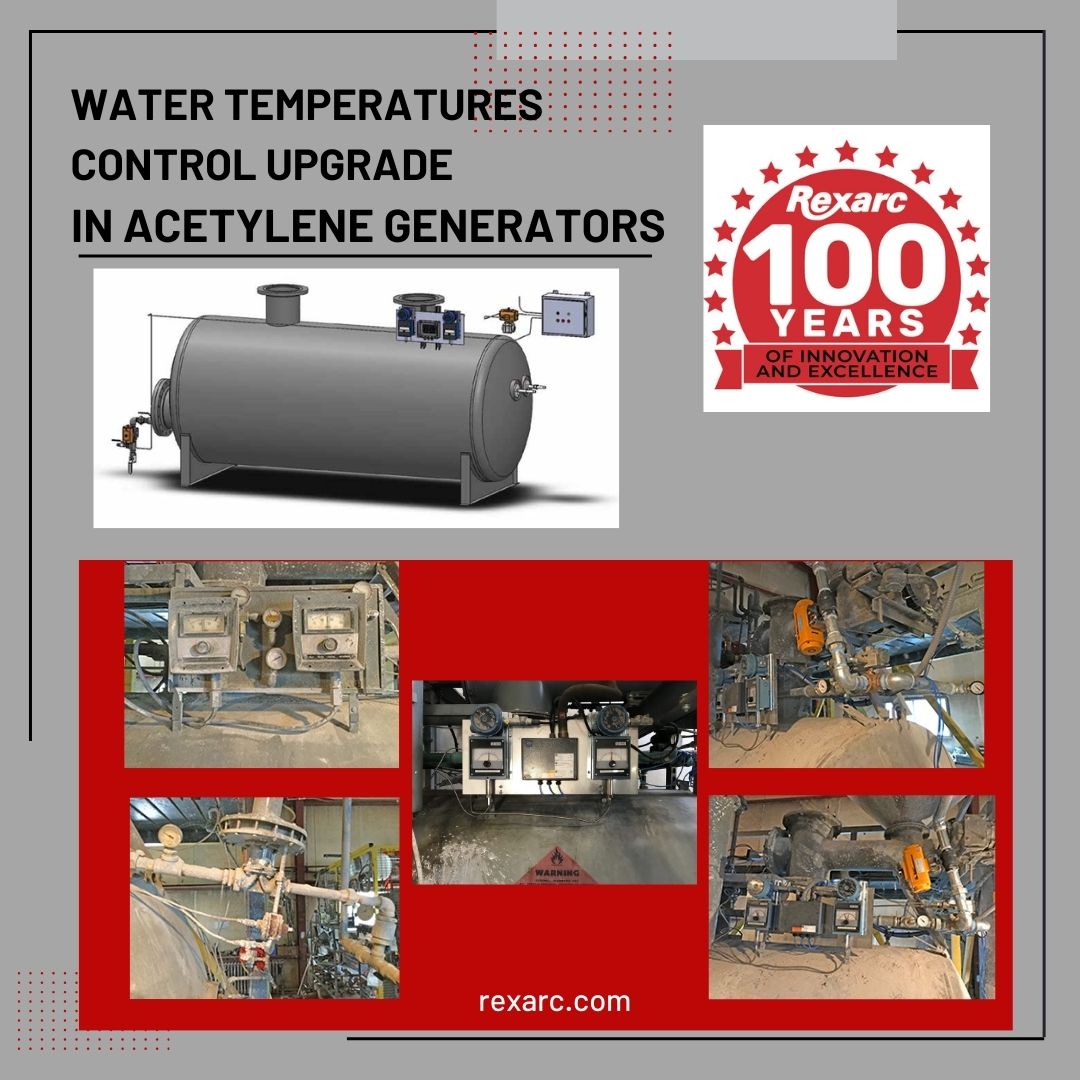

Rexarc offers advanced water/temperature control systems for its Model ATX and AX generators as well as any other medium sized acetylene generator. These innovative systems help control temperature/water so the plant operates efficiently at low load and helps prevent the...

View Details

Could your acetylene operations benefit from an ammonia scrubber? What is Ammonia: Ammonia is a colorless gas composed of nitrogen and hydrogen that has a distinct pungent smell and is widely used in various applications. However, ammonia is hazardous and...

View Details

Any gas distribution system needs to have the right pipe diameter to work efficiently and ensure the right amount of gas is available where it needs to be. This guide will help you figure out what pipe diameter will be...

View Details

High purity acetylene has a wide range of uses, including flame spectroscopy, production of some plastics and chemicals, as a light source in places without access to electricity, and most commonly, as a fuel across industries. This article will help...

View Details

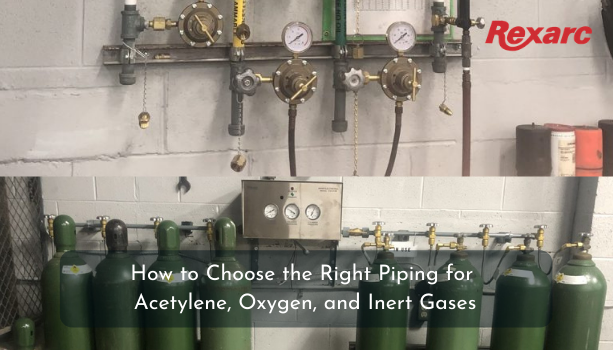

Acetylene, oxygen, and inert gases are industrial gases, which find applications across industries. Oxygen-acetylene combination produces localized heat, and is widely used for different types of heating applications. Be it acetylene, oxygen, or inert gases, each of these have typical...

View Details

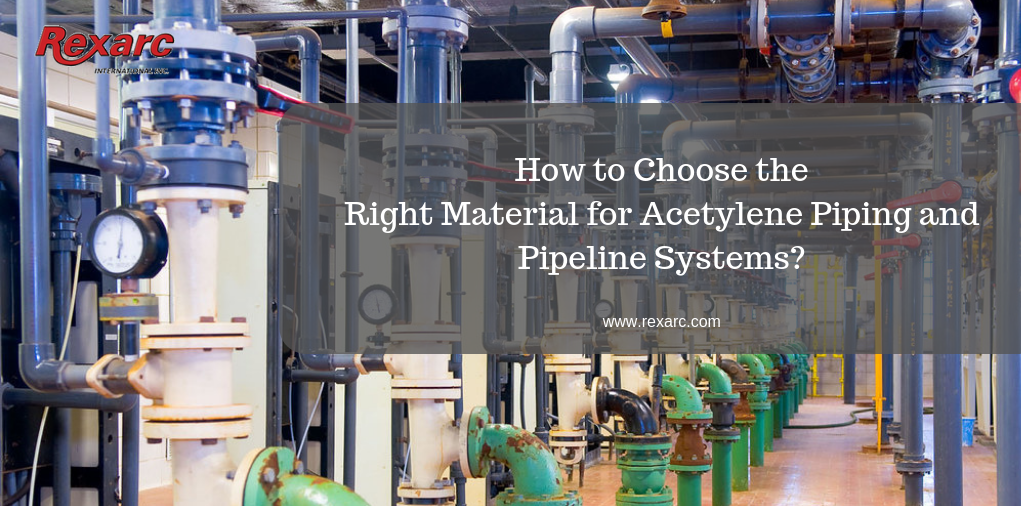

Acetylene is today considered one of the most popular industrial gases, which is distributed through manufacturing plants in pipelines and manifolds. Along with acetylene, oxygen and other inert gases are also used in various industrial applications. These pipelines and manifolds...

View Details

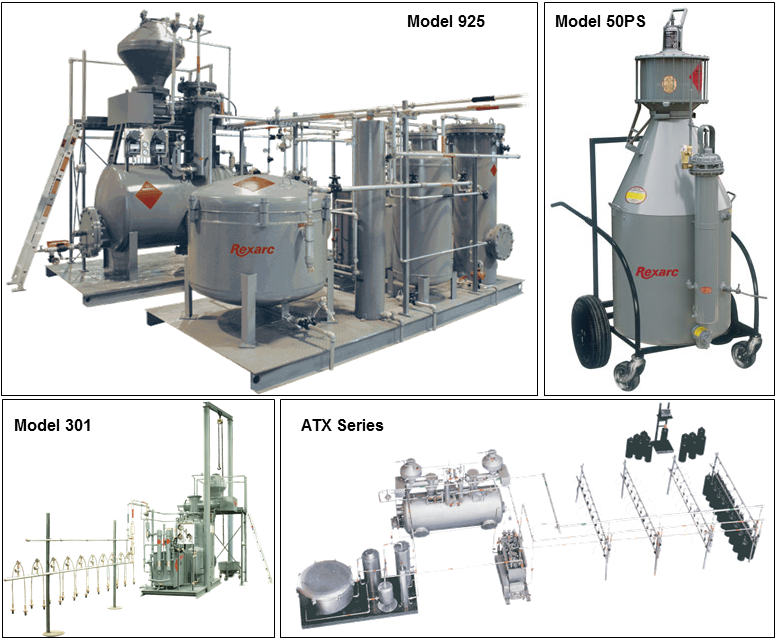

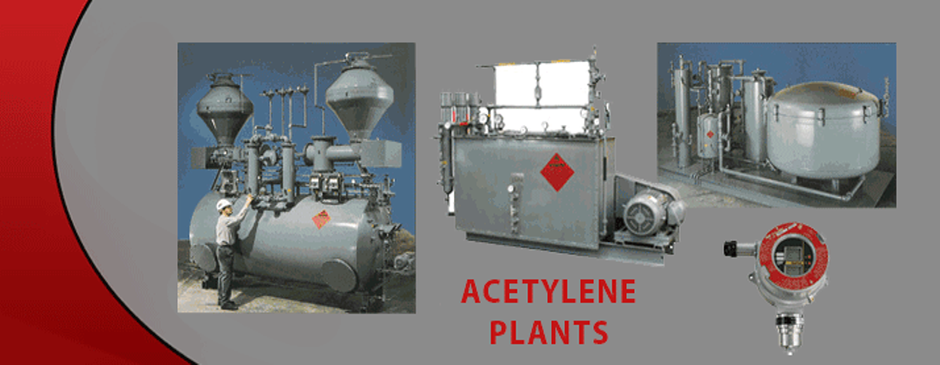

Acetylene gas plants are used for various continuous process applications such as for ethylene production in the chemical industry, in the metal fabrication industry for oxy-acetylene welding, cutting, brazing, and so on. There are several acetylene gas plant manufacturers in...

View Details

Acetylene is one of the most popular gases used across industries for oxy-acetylene welding and cutting. It is also used as a raw material for the production of various chemicals such as polyester plastics, polyurethane, and more. Acetylene gas is...

View Details

Acetylene, being one of the widely used compressed gases, is nowadays produced on a larger scale using acetylene plants. As with any regular compressed gas generation equipment, these plants are fitted with several parts that play a key role in...

View Details

Over the years, the use of several compressed gases in industries has increased. Acetylene is one such gas that has gained immense popularity in various industries because of the several benefits it offers. Today, acetylene production and filling plants are...

View Details

Acetylene is an industrial gas with several beneficial properties, which makes it easily popular over other industrial gases such as methane, propane, and so on. Though all these gases are hydrocarbons, the acetylene differs from them in terms of its...

View Details

Acetylene (C2H2) is a highly flammable gas; it is colorless and has a peculiar odor. Acetylene gas plants are units where acetylene gas production is carried out. At the plant, acetylene is produced either through a chemical reaction or cracking...

View Details

Pressure vessels serve different purposes, and they are used across various industries. These vessels may be compressed with different types of industrial gases. Some common gasses include air, acetylene, helium, oxygen, or nitrogen. Being a popular industrial gas, acetylene is...

View Details

Safe and health-friendly workplaces are a necessity in every country. In the United States of America, Occupational Safety and Health Administration (OSHA) directs employers to assure workplaces that are safe to work, and ensures their safety and wellbeing. All industries...

View Details

A regularly scheduled plant audit is highly recommended for any manufacturing and processing plant dealing with chemicals and complex manufacturing procedures. A plant audit involves inspection by experienced specialists from the organization that supplied key equipment to a process or...

View Details

An acetylene plant audit should be conducted on a regular basis to verify the state of the components. A professional will be able to help streamline processes to increase the overall efficiency of your acetylene plant. This is extremely important...

View Details

This is a four-part blog series related to some of the problems uncovered during plant audits. These posts should give you a good idea of the various machines and components of an acetylene plant to look at, in case you...

View Details

Personal Protective Equipment (PPE) is used to manage safety and health related risks in a workplace. Depending on the equipment and raw materials being used, as well as the product being manufactured, the right PPE should be used. In an...

View Details

In acetylene plants, carbide lime is generated as a byproduct. Carbide lime is further processed to make it useful in other industries and applications. Most acetylene manufacturing plants using the wet acetylene generating process, install a carbide lime treatment plant...

View Details

In the previous post, we discussed three common problems observed in acetylene plants. The following are some more areas that should be looked into during an acetylene plant audit. Common Acetylene Plant Problems – What are They & How to...

View Details

The state of components and equipment in an acetylene plant will determine the efficiency and safety of the plant. Since acetylene is a volatile substance, excessive care should be taken to maintain the equipment used to handle it. Identifying the...

View Details

In a job, an employee might be required to perform the same job repeatedly. Such repetitive motions have the potential to cause serious injury to the employee. In acetylene plants, several such jobs can be identified that could cause physical...

View Details

In the earlier posts, we discussed the major benefits of preventive maintenance in an acetylene plant including lowering of costs. In this post, the plan for preventive maintenance in acetylene plants is outlined. How to Plan for Preventive Maintenance In...

View Details

In the earlier post, we discussed the main differences between reactive and preventive maintenance. There are several reasons why one should opt for preventive maintenance in acetylene plants. These are explained in detail below. Preparing for Reactive/ Breakdown Maintenance Although...

View Details

Preventive maintenance is the key to high performing equipment and streamlined operations. This process can help a company minimize losses associated with part failure and unplanned shutdowns. Preventive maintenance is repair work that is performed periodically on all the functional...

View Details

The commercial uses of acetylene have been discussed in detail in the earlier post, Commercially Viable Uses of Acetylene – Part I. This is a continuation of the same topic. Acetylene production plants produce acetylene with various levels of purity. This...

View Details

Acetylene production plants produce acetylene for various industrial and commercial purposes. Acetylene gas features properties that make it an extremely useful gas in various applications and industries. Acetylene is mainly manufactured for chemical synthesis. The second most common application of...

View Details

Acetylene cylinder filling plants are used in the production of acetylene. Low and medium pressure systems can be used for the gas generation process. The process will be chosen depending on the required yield of acetylene. Several provisions are in...

View Details

Nitrogen purging forms an integral part of safe and efficient functioning of an acetylene gas production plant. This process should be incorporated by all acetylene gas plant owners. This is an internal cleaning process employed to free pipes and other...

View Details

Huge amounts of industrial waste are generated around the world. This waste can be harmful to the environment if not disposed properly, or the disposal of the same could lead to very high costs. On the other hand, utilizing industrial...

View Details

We are a one stop shop from custom vessel production to full skidding, plumbing and instrumentation.

We stand by our processes and communicate with you on your project status as much or as little as you would like.

We continually reinvest in our people, business, and equipment technology to ship quality products on time.