Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Pressure vessels serve different purposes, and they are used across various industries. These vessels may be compressed with different types of industrial gases. Some common gasses include air, acetylene, helium, oxygen, or nitrogen. Being a popular industrial gas, acetylene is...

View Details

Acetylene is one of the popular industrial gases used across the world. The gas offers several advantages which has contributed to its widespread use across various industries. Although human-friendly, the gas also possesses several hazardous properties, which may lead to...

View Details

Industrial gas cylinders have been around for a long time. They are widely used for welding, medical applications, fermenting liquids, and several other applications across various industries. In addition to these, new applications for these cylinders are emerging, as new...

View Details

Acetylene gas is a product gas, which is manufactured for use in different industries such as manufacturing, petrochemicals, biotechnology, environmental protection, etc. Like other industrial gases, this gas also has several impurities such as particulates, organic and inorganic matter, water,...

View Details

Safety hoses are important in industries where liquids and gases get moved. Most times, these hoses are made from sturdy materials, which helps improve their performance in harsh conditions. Do you think the sturdiest construction is enough to ensure its...

View Details

Hoses get used in industrial facilities dealing with different types of gases. These are hollow and flexible tubes, which get used to pack dissolved gases such as acetylene, and atmospheric gases such as oxygen, and argon in cylinders or for...

View Details

Rexarc, a market leader in acetylene gas plant solutions, is committed to creating awareness about risks and hazards associated with the industrial applications of acetylene gas generator equipment. To fulfill this commitment, the company has decided to make its presence...

View Details

Safe and health-friendly workplaces are a necessity in every country. In the United States of America, Occupational Safety and Health Administration (OSHA) directs employers to assure workplaces that are safe to work, and ensures their safety and wellbeing. All industries...

View Details

When it comes to compressed gas products, many business owners and managers prefer buying new ones. Many times, this is due to a gap in their understanding of the benefits of the rebuilding process or even that rebuilt units are...

View Details

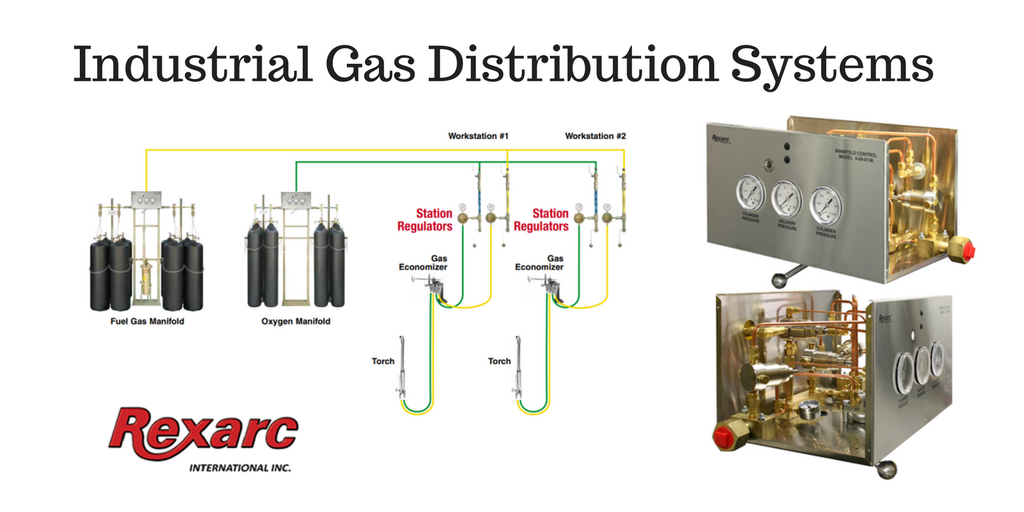

The concept of manifolding has been around in the welding, gases, and hardgoods industry for a long time. While it is a general term used in the compressed gas industry and can mean many things, this article focuses on manifolding...

View Details

We would like to utilize this opportunity to thank you and all other business partners, current and prospective clients for visiting us at booth #13 at Gasworld Conference, Dubai. It was a great event for the team. Our team is...

View Details

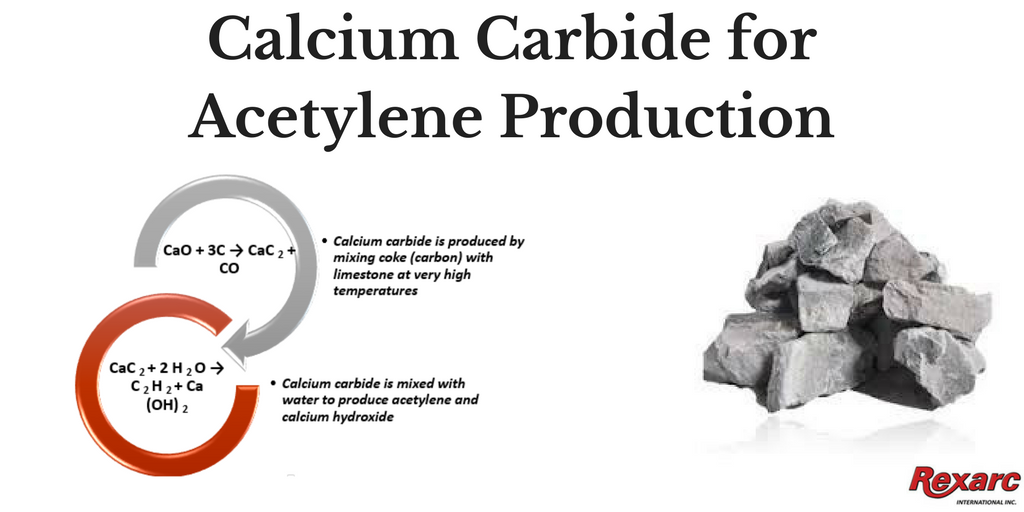

Acetylene is a combustible gas with a distinctive odor. It is used as a raw material for the production of several organic chemicals, as well as a fuel component in metal cutting, and oxy-acetylene welding. Today, acetylene is also used...

View Details

Rexarc, a leading manufacturer of acetylene gas plants, is looking forward to the next major gas industry event – the Middle East and North Africa (MENA) Industrial Gas Conference 2017. The event will be taking place from 18th – 20th...

View Details

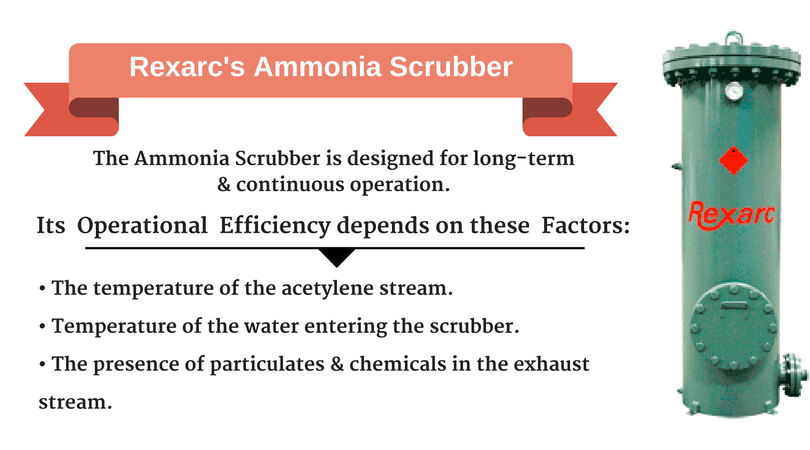

Ammonia gas is a very common by-product of chemical processes. Chemical manufacturers are required to reduce their ammonia gas emissions because it is classified as a hazardous substance by the United States Emergency Planning and Community Right-to-Know Act (EPCRA). There...

View Details

The Global Harmonization System of Classification and Labelling is developed by the United Nations to standardize the use of hazardous chemicals around the globe. Abbreviated as GHS, this system standardizes the use of chemicals on the basis of their health,...

View Details

A regularly scheduled plant audit is highly recommended for any manufacturing and processing plant dealing with chemicals and complex manufacturing procedures. A plant audit involves inspection by experienced specialists from the organization that supplied key equipment to a process or...

View Details

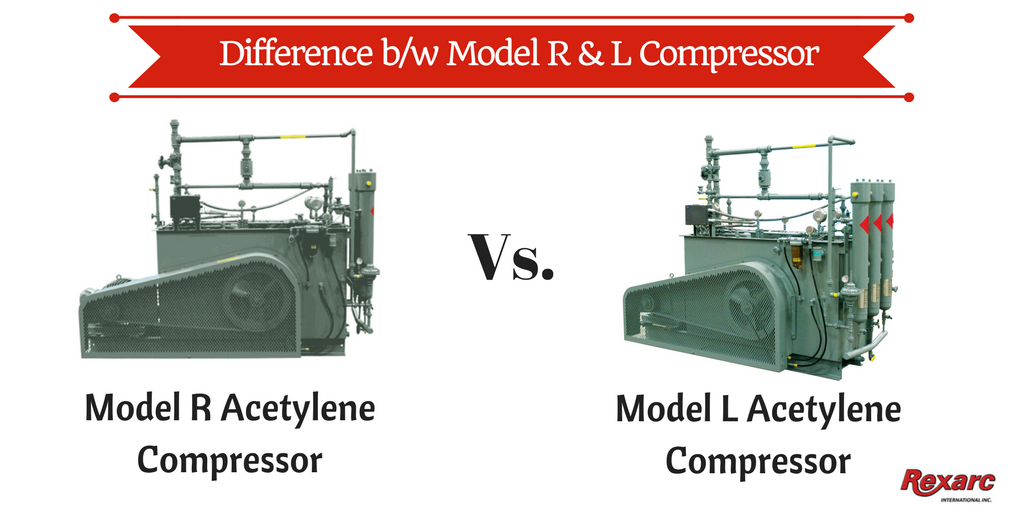

This is a common question when a company asks about the compressor options available from Rexarc. Here’s a brief overview of the similarities between the Rexarc Model L and Model R acetylene compressors as well as the positives and negatives...

View Details

For the second year in a row Rexarc International has chosen to have the CSR initiative - Giving Tree. To inspire the giving of employees, Rexarc matched each employee gift of a hat and/or gloves. The initiative was well-received again...

View Details

Globalization has been a boon for organizations in many industries. It has been an opportunity to create partnerships, as well as find ways to make an impact in international markets. To ensure success in export markets, organizations need to understand...

View Details

Unlike most industrial gases, Acetylene is a type of gas that is dissolved into a solvent to keep it safer and more stable. Due to its chemical composition it is an extremely useful gas for the chemical industry but for...

View Details

An acetylene plant audit should be conducted on a regular basis to verify the state of the components. A professional will be able to help streamline processes to increase the overall efficiency of your acetylene plant. This is extremely important...

View Details

This is a four-part blog series related to some of the problems uncovered during plant audits. These posts should give you a good idea of the various machines and components of an acetylene plant to look at, in case you...

View Details

Personal Protective Equipment (PPE) is used to manage safety and health related risks in a workplace. Depending on the equipment and raw materials being used, as well as the product being manufactured, the right PPE should be used. In an...

View Details

In acetylene plants, carbide lime is generated as a byproduct. Carbide lime is further processed to make it useful in other industries and applications. Most acetylene manufacturing plants using the wet acetylene generating process, install a carbide lime treatment plant...

View Details

In the previous post, we discussed three common problems observed in acetylene plants. The following are some more areas that should be looked into during an acetylene plant audit. Common Acetylene Plant Problems – What are They & How to...

View Details

The state of components and equipment in an acetylene plant will determine the efficiency and safety of the plant. Since acetylene is a volatile substance, excessive care should be taken to maintain the equipment used to handle it. Identifying the...

View Details

In a job, an employee might be required to perform the same job repeatedly. Such repetitive motions have the potential to cause serious injury to the employee. In acetylene plants, several such jobs can be identified that could cause physical...

View Details

During the process of acetylene production, the chemical reaction produces some amount of heat. The amount of heat dispelled during generation is monitored to ensure that it is not excessive. Heat is further reduced during the purification process and under...

View Details

In the earlier posts, we discussed the major benefits of preventive maintenance in an acetylene plant including lowering of costs. In this post, the plan for preventive maintenance in acetylene plants is outlined. How to Plan for Preventive Maintenance In...

View Details

In the earlier post, we discussed the main differences between reactive and preventive maintenance. There are several reasons why one should opt for preventive maintenance in acetylene plants. These are explained in detail below. Preparing for Reactive/ Breakdown Maintenance Although...

View Details

Preventive maintenance is the key to high performing equipment and streamlined operations. This process can help a company minimize losses associated with part failure and unplanned shutdowns. Preventive maintenance is repair work that is performed periodically on all the functional...

View Details

The commercial uses of acetylene have been discussed in detail in the earlier post, Commercially Viable Uses of Acetylene – Part I. This is a continuation of the same topic. Acetylene production plants produce acetylene with various levels of purity. This...

View Details

Acetylene production plants produce acetylene for various industrial and commercial purposes. Acetylene gas features properties that make it an extremely useful gas in various applications and industries. Acetylene is mainly manufactured for chemical synthesis. The second most common application of...

View Details

Acetylene gas is mixed in liquid acetone for safe storage and usage. Acetone in acetylene cylinders helps stabilize the gas making it non-reactive within the cylinder. In this process, acetylene is dissolved in liquid acetone under high pressure. The cylinder...

View Details

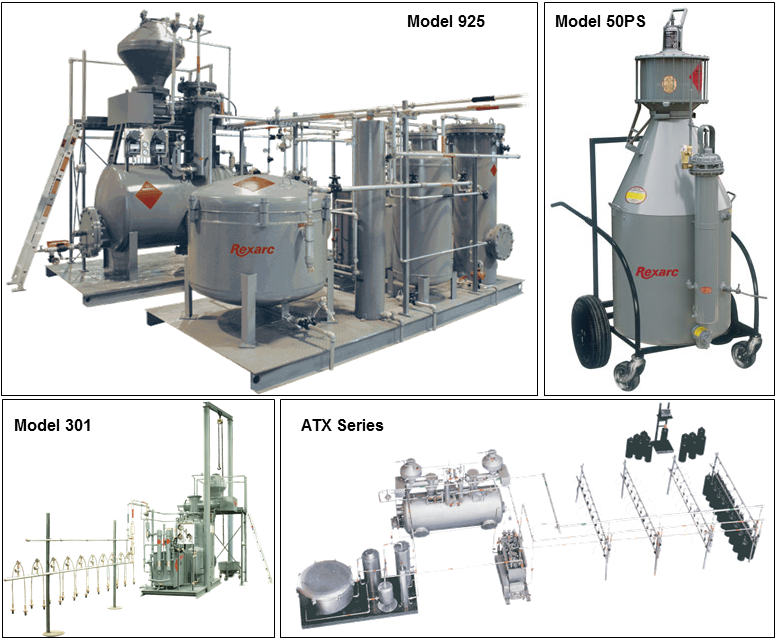

Acetylene cylinder filling plants are used in the production of acetylene. Low and medium pressure systems can be used for the gas generation process. The process will be chosen depending on the required yield of acetylene. Several provisions are in...

View Details

Nitrogen purging forms an integral part of safe and efficient functioning of an acetylene gas production plant. This process should be incorporated by all acetylene gas plant owners. This is an internal cleaning process employed to free pipes and other...

View Details

Flashback arresters are one of the most important safety and hazard prevention tools available. Flashback arresters are used in industries where explosive gases are transferred from one location to another. This safety device is essential in large industrial set-ups as...

View Details

Huge amounts of industrial waste are generated around the world. This waste can be harmful to the environment if not disposed properly, or the disposal of the same could lead to very high costs. On the other hand, utilizing industrial...

View Details

Gas regulators are responsible for pressure maintenance and shutting off the flow of gas or liquid. Acting as valves, the regulators come in various types and are made of different materials. Dual stage brass barstock regulators are one such type...

View DetailsVarious industrial, as well as commercial applications require superior quality stainless steel regulators for pressure control in gas and/or liquid systems. Selection of the right type of regulator is very important because they may be used in hostile environments with...

View Details

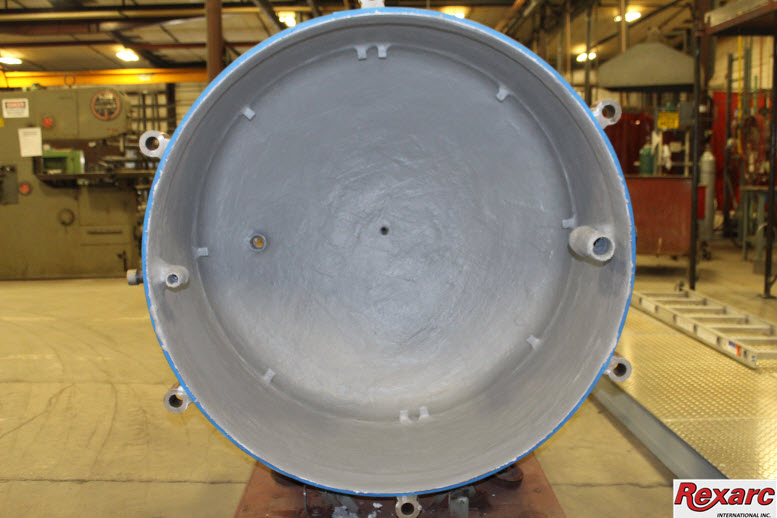

We are a one stop shop from custom vessel production to full skidding, plumbing and instrumentation.

We stand by our processes and communicate with you on your project status as much or as little as you would like.

We continually reinvest in our people, business, and equipment technology to ship quality products on time.